We are officially in the Digital age where smartphone usage is more than laptop or desktop utilization. The % of people shopping through their phones continues to increase. A third of the world’s population interacts through social media portals (Facebook, Google+, Instagram, Twitter etc.) And it is estimated that that CMOs spent $135 billion USD(1) on digital marketing last year.

While digital transformation drove a lot of new trends in supply chain as executives started to think about collaboration, analytics and a consumer centric supply chain, many could not figure out a path forward. 2015 and the next couple of years are going to be hot for supply chain. So fasten your seat belt and start thinking about how YOU will transform your supply chain.

Top analysts like Gartner predict that there will be 43 trillion GB of data by 2020 and 8 billion sensors(2) will be operational. We are seeing the industry gearing for Internet of Things and 3D printing, both of which will generate even more data. CMOs will continue to invest in customer engagement. Supply chain executives need to think about how will they integrate better with customer facing digitization, and what a new supply chain that could leverage all this data would look like.

Top analysts like Gartner predict that there will be 43 trillion GB of data by 2020 and 8 billion sensors(2) will be operational. We are seeing the industry gearing for Internet of Things and 3D printing, both of which will generate even more data. CMOs will continue to invest in customer engagement. Supply chain executives need to think about how will they integrate better with customer facing digitization, and what a new supply chain that could leverage all this data would look like.

Supply Chain analytics will become critical to create competitive advantage. Companies would need to develop multiple supply chains to align with their customer segments and one size fits all won’t work any more. The key would be to create an agile supply chain that operates on early sensing based on consumer data and can respond quickly without increasing operating cost. While analytics will help improve the bottom line, supply chain could get a seat on the table by improving revenue with offerings like co-innovation with customers and better integration with front end customer segmentation.

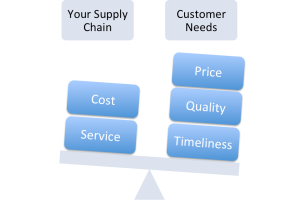

A good example would be from Retail and CPG where companies are trying to allure customers with new promotions tailored specifically to a region and sometimes even zip codes. We have seen that today’s customers not only look for better price but they  want timely delivery of goods and services with quality. So if you would have worked with your marketing team, you would be able to re-organize your network and inventory position to match those promotions in a cost effective way while delivering on price, time and quality. Although it might sound like you do it already, I would bet No! Key is how quickly can you re-organize for the next promotion while maintaining competitiveness and leadership in consumer demand. This is just one use case amongst hundreds but all predicated on Analytics and Collaboration.

want timely delivery of goods and services with quality. So if you would have worked with your marketing team, you would be able to re-organize your network and inventory position to match those promotions in a cost effective way while delivering on price, time and quality. Although it might sound like you do it already, I would bet No! Key is how quickly can you re-organize for the next promotion while maintaining competitiveness and leadership in consumer demand. This is just one use case amongst hundreds but all predicated on Analytics and Collaboration.

How do you drive collaboration?

Supply chain executives would need to change the traditional metrics model and align operations with two goals – customer value and shareholder value. These are also the primary goals of any organization but when you look within your supply chains, you will find that cost is the primary driver and metrics are built around that. So establish a cross-functional group comprising of plan, source, make and deliver experts along with some data scientists to develop use cases that would align the supply chain with the two goals. And have this group work closely with marketing and R&D teams so that they can identify early and better ways to collaborate with suppliers and manufacturer. You will be surprised to see the outcome of such a think tank. And most importantly, make sure there is executive support without which such initiatives don’t deliver value.

One concern that comes up all the time is the lack of technology to support all these changes. My short response to it – get over it and get your CIO in your next meeting. Technology should not be a barrier any more. ERP leaders like SAP, Oracle and JDA have made huge investments to bring new innovations to the market, and there are hundreds of specialized niche firms offering world-class services with new technologies and innovations. I understand the initial investment but if you rationalize your ROI with the two goals I listed earlier, you will find a better business case (rather than cost savings only based on business case).

Now let’s quickly look into some of the industry specific trends that you should focus on.

Retail – Omnichannel. Last year retailers figured out a recipe to combat e-commerce but are not necessarily doing it right. Most are still working on operationalizing it. So your 2015 focus should be on how to do omni-channel right such that you can increase shareholder value while maintaining customer value.

Manufacturing – beware of 3D printing. Naysayers believe it will not have material impact but most tech companies are launching commercial and home-use 3D printers in 2015-16. Rather than fighting it, embrace it and see what products can move to 3d printing and create a new service model for you. And continue to focus on co-innovation with customers and business partners.

Life Sciences – what a year 2014 was with all the acquisitions. While you are focusing on patient safety and traceability, look at managing the supply chain assets as part of your M&A. Supply chain optimization should be a focus for executives to drive a safe and efficient supply chain.

Consumer products – just like the retailers, you are facing a stiff competition with e-commerce, rising imported product, razor thin margins and startups. What this industry had started few years ago and most companies did not do it right, should be back in focus – demand driven supply networks. And add social media insights to it. Drive analytics deep into the organization and restructure your supply chain.

I am excited about 2015 and the next few years. There should be a lot of innovation with the changes in supply chain. Here is my podcast with SAPInsider on this topic and I hope to connect with many of you at the SCM Conference in Las Vegas on March 30, 2015 (3).